Sustainable concrete and 3D printing at Purdue University

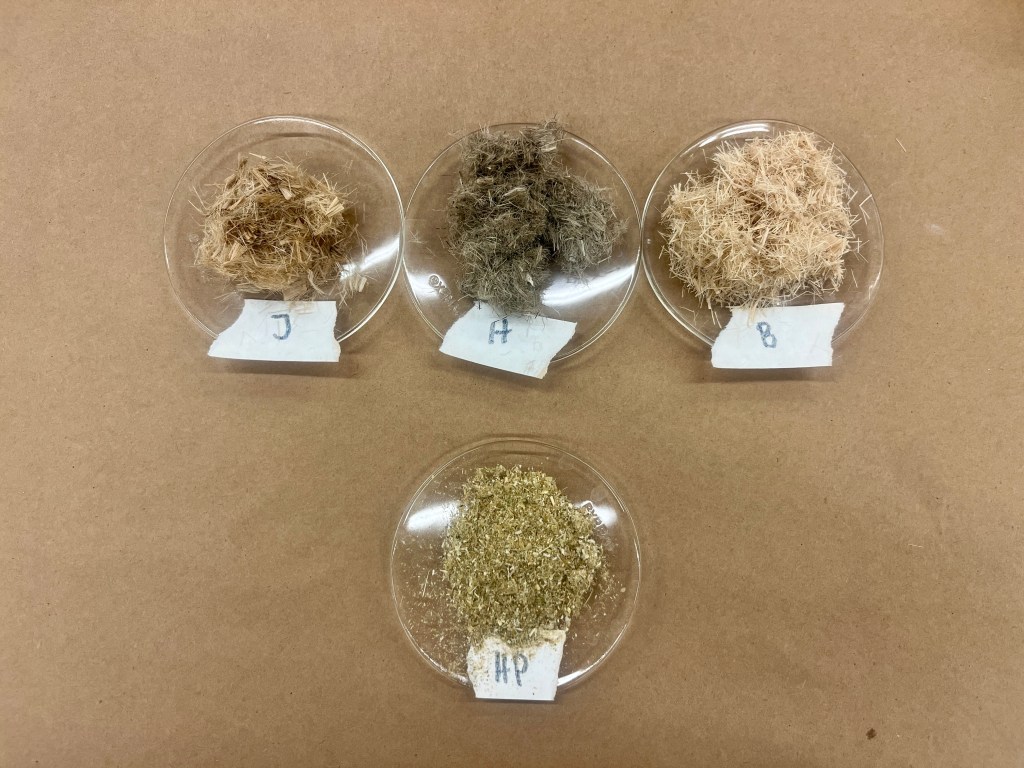

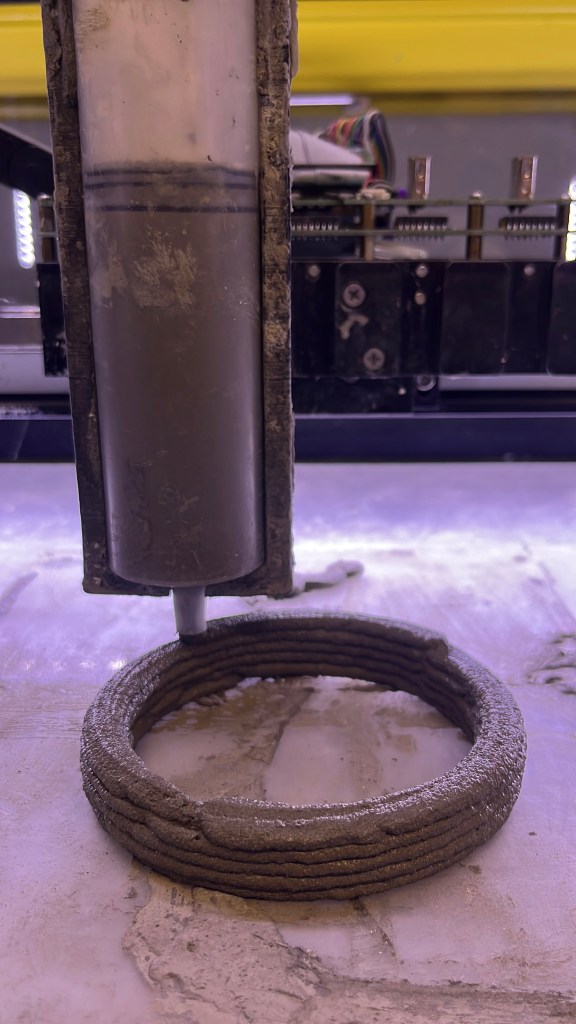

Since March, LTU PhD researcher Magdalena Rajczakowska has been a Fulbright Scholar at Purdue University, USA, experimenting with multiscale plant-based fibers in 3D-printed concrete. Studies report that cellulose-rich printable mortars can reduce embodied CO₂ by approximately 30% while maintaining sufficient stiffness to hold their shape. Initial results from Magdalena’s tests suggest that the material can be printed without negatively affecting buildability.

Concrete additive manufacturing is already reshaping offshore construction: GE Renewable Energy, COBOD, and Holcim have 3D-printed a 10 m concrete wind-turbine pedestal in Denmark, demonstrating that on-site fabrication could scale towers to 200 m while reducing transport and formwork needs. In the North Sea, the Port of Rotterdam has installed interlocking 3D-printed “Reefblocks” that serve both as scour protection and artificial habitat, confirming printed concrete’s durability in marine conditions.

With Nordic mega-projects like the Korsnas offshore wind farm, could the next offshore foundation be printed right here in the Aurora region